Convert structural drawings into high-precision mold processing systems to provide high-precision plastic molds for injection molding production.

What are plastic molds?

Plastic molds are used to make plastic products. The mold contains a cavity that is made in the shape and size of the product that needs to be made. Plastic is then injected into the cavity, and once the plastic cools and solidifies, the mold is opened, and the finished product is extracted. This process is known as injection molding.

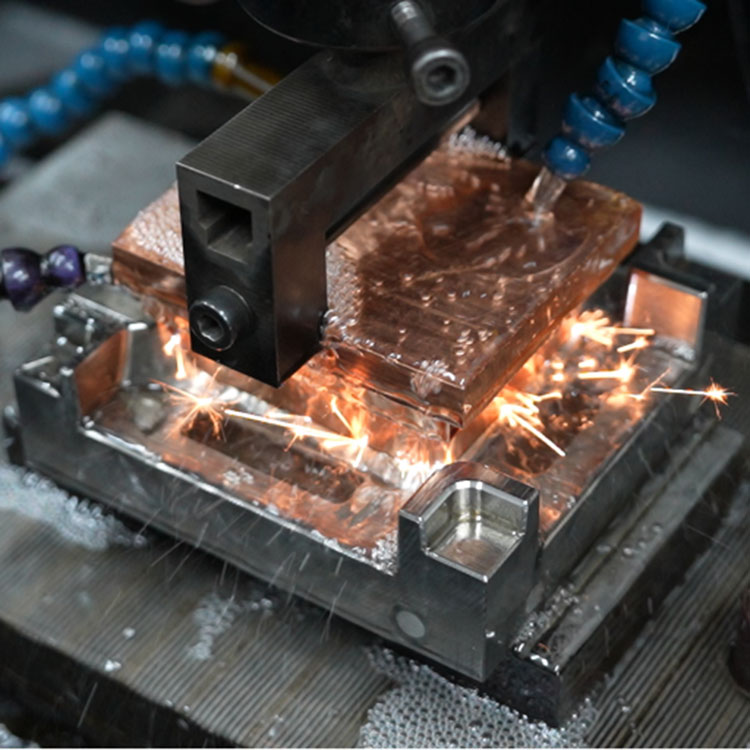

The mold company is strong, with world-class mold R&D strength and profound mold professional technology. It has a mold engineer R&D and technical support team composed of more than 30 mold technical talents with bachelor's degrees or above (including more than 10 high-end mold R&D engineers, more than 30 professional mold manufacturing engineers, mold and product designers); it has mold CNC processing centers, mold computer spark machines, mold data control gong beds, mold computer injection molding machines and other foreign advanced mold processing equipment, equipped with professional spray painting, silk screen, pad printing and other mold shell production lines, with the introduction of foreign advanced technology and technology and mold finished product design and assembly, adopting modern mold management mode, and implementing comprehensive mold quality management and mold service system.